8RX 410Tractor

- 443 hp (326 kW) Max Power (ECE-R120) + 15 hp (11 kW)

- 9.0 l engine with 6 cylinders

- 18.7 t and 3,235 m wheelbase

- New bigger and more comfortable CommandView Cab with new level of visibility

The DLG awarded the new eAutoPowr with the only gold medal at Agritechnica 2019.

MORE WITH LESS

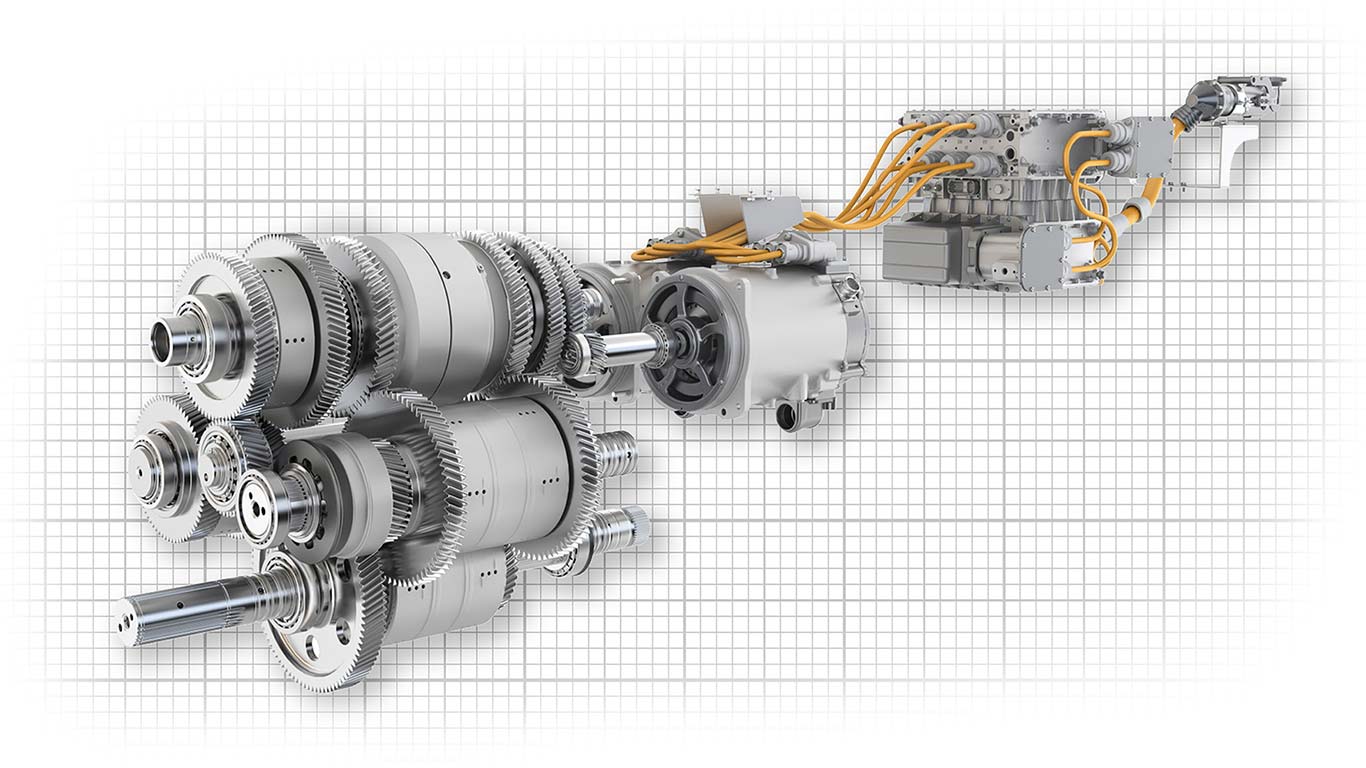

The eAutoPowr™ transmission, available for the 370 and 410 models of 8R, 8RT and 8RX tractors features a straightforward design with less complex parts. We have replaced hydro modules with electrical components to achieve maximum performance, reliability, and comfort.

It features maintenance-free, liquid-cooled, brushless electric motor generators. The use of electric components over hydro modules simplifies design, increases efficiency, reduces wear parts, and extends transmission lifespan.

The eAutoPowr™ is the most versatile and powerful option in the 8 Series transmissions, blending AutoPowr™ efficiency with e23™ muscles. Seamless shifting with solid-state power electronics delivers instant torque for the smoothest ride, even in the most challenging applications.

Its electric start-off delivers immediate power and torque, enabling quicker, smoother direction changes and precise creeper speeds, thanks to its use of electric motors over hydro modules.

Featuring the CommandPRO™ interface identical to AutoPowr™, eAutoPowr™ offers all known CommandPRO comfort features and easy setup through the G5Plus CommandCenter™ display. Its electric motors reduce cabin noise by 23% compared to hydro modules.

eAutoPowr allows offboarding of up to 100 kW 480V AC for external consumers via an optional AEF outlet socket. This electric power can be used e.g. to power drive axles from implements. Electrically driven axles provide a significant increase in traction, a reduction of wheel slip and prevention of ballasting. This enables a higher area output by using much wider incorporation tools for lower application costs per hectare, paired with a higher soil protection.

“The noise in the Cab is more silent than we’re used to in our current 8R Series”

Christian Sommerlund, JSJ-Agro, Danmark

Professionals who already experienced eAutoPowr™ are thrilled. See for yourself.

So much space, so little noise, such luxury. Pure passion for detail. Welcome to the new 8R cab, bigger and even more comfortable than ever.

UNSTOPPABLE POWER

If minimum soil disturbance is a priority for you, there is no way around the 8RX. It’s ideal for difficult side-hill terrain and soil types. Plus you’ll benefit from maximum operating windows.

The bold design of the 8R/RT/RX Series tractors announces what they’re all about: pulling power that stops for nothing and technology that moves modern farming forward.

| Specifications | ||||

|---|---|---|---|---|

| John Deere 8RX 410 Tractor |

| Engine description | John Deere PowerTech™ PSS 9.0 L (B20 diesel compatible) | |||

|---|---|---|---|---|

| Engine displacement | 9.0 L 549 cu in. |

|||

| Rated engine power | ECE-R120: 302 kW 410 hp |

|||

| Maximum engine power | ECE-R120: 326 kW 443 hp |

|||

| Rated PTO power (hp SAE) | 231 kW 310 hp |

|||

| Maximum PTO power | ||||

| Transmission type | Standard: e23™ PowerShift™ with Efficiency Manager™ 40K, 40 km/h (24.9 mph) Optional: John Deere eAutoPowr™ EVT™ 40K, 0.05-42 km/h (0.03-26 mph) |

|||

| Hydraulic pump rated output | Standard: 85-cc pump: 227.1 L/min 60 gpm Optional: 85-cc plus 35-cc dual pump: 318 L/min 84 gpm |

|||

| Rear hitch category (SAE designation) | Standard: Category 4N/3 standard lift at 610 mm (24 in.) behind hitchpoint: 9072 kg 20,000 lb Optional: Category 4N/3 at 610 mm (24 in.) behind hitchpoint: 6,803 kg 15,000 lb |

|||

| Base machine weight | e23, 457-mm (18-in.) front/rear and 3048-mm (120-in.) tread: 19,591 kg 43,100 lb |

|||

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | ||||

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) |

| Description | John Deere PowerTech™ PSS 9.0 L (B20 diesel compatible) | |||

|---|---|---|---|---|

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with four valves in head | |||

| Engine family | MJDXL09.0333 | |||

| Rated speed | 2100 rpm | |||

| Aspiration | Dual turbochargers, variable geometry turbo with fixed geometry turbo in series; air-to-air aftercooling and cooled exhaust gas recirculation | |||

| Cylinders liners | Wet-sleeve | |||

| Emission level | Stage V | |||

| After treatment type | Diesel oxidation catalyst (DOC)/diesel particulate filter (DPF)/selective catalytic reduction (SCR) | |||

| Displacement | 9.0 L 549 cu in. |

| Rated power | ECE-R120: 302 kW 410 hp |

|||

|---|---|---|---|---|

| Rated PTO power (hp SAE) | 231 kW 310 hp |

|||

| Maximum PTO power | ||||

| Intelligent Power Management (IPM) | ||||

| Power boost | 8 percent | |||

| Maximum engine power | ECE-R120: 326 kW 443 hp |

|||

| Engine peak torque | At 1600 rpm: 1851 Nm 1365 lb-ft |

|||

| Drawbar power | ||||

| PTO torque rise | 40 percent | |||

| Fuel injection system and control | ||||

| Air cleaner type | ||||

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | ||||

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) |

| Type | Standard: e23™ PowerShift™ with Efficiency Manager™ 40K, 40 km/h (24.9 mph) Optional: John Deere eAutoPowr EVT 40K, 0.05-42 km/h (0.03-26 mph) |

|||

|---|---|---|---|---|

| Reverser | ||||

| Clutch; wet/dry | ||||

| Creeper | ||||

| Integrated Electric Power Generation |

| Type | Closed-center, pressure/flow compensated system with load sensing | |||

|---|---|---|---|---|

| Pump rated output | Standard: 85-cc pump: 227.1 L/min 60 gpm Optional: 85-cc plus 35-cc dual pump: 318 L/min 84 gpm |

|||

| Available flow at a single rear SCV | 1.3-cm (1/2-in.) couplers: 132 L/min 35 gpm 1.9-cm (3/4-in.) coupler: 132 L/min |

|||

| Available flow at front SCVs | 96 L/min 25 gpm |

|||

| Number of rear selective control valves (SCVs) | Standard: 1.3-cm (1/2-in.) ISO couplers: 4 Optional: 1.3-cm (1/2-in.) ISO couplers: 5 and 6 available 1.9-cm (3/4-in.) ISO coupler: 1 |

|||

| Number of mid selective control valves (SCVs) | ||||

| Number of front selective control valves (SCVs) | ||||

| Joystick SCV control | ||||

| Auxiliary hydraulic features | ||||

| SCV control | Electronic |

| Hitch draft control load sense type | ||||

|---|---|---|---|---|

| Remote control valves available | ||||

| Hitch category (SAE designation) | Standard: Category 4N/3 standard lift at 610 mm (24 in.) behind hitchpoint: 9072 kg 20,000 lb Optional: Category 4N/3 at 610 mm (24 in.) behind hitchpoint: 6,803 kg 15,000 lb |

|||

| Maximum lift capacity behind lift points | Standard (at 610-mm [24-in.] behind hitch point): 12,124 kg 26,729 lb |

|||

| Lift capacity at standard frame | ||||

| Sensing type | Electrohydraulic | |||

| Rear axle differential lock | ||||

| Rear hitch lift capacity (SAE designation) |

| Drawbar category | Standard: Category 4 Optional: Category 4 with heavy-duty support |

|||

|---|---|---|---|---|

| Maximum vertical load | Standard: 2245 kg 4950 lb Optional (dependent on drawbar position): 3,000 kg 6,614 lb |

| Type | Independent Standard: 44 mm (1.75 in.) 20-spline, 1,000 rpm Optional: 44 mm (1.75 in.) 20-spline, 1,000 rpm/1,000E rpm |

|||

|---|---|---|---|---|

| Engine rpm (at rated PTO speeds) | e23 PowerShift: 1,000 PTO rpm at 1,995 engine rpm, 1,000 ECO PTO at 1,590 engine rpm, 540 PTO rpm at 1,810 engine rpm | |||

| Economy PTO speeds | ||||

| Reverse PTO speeds | ||||

| Multispeed PTO option availability | Available: 45-mm (1.75-in.), 1000-rpm and 1000E economy rpm PTO, in-cab shiftable | |||

| Ground speed PTO option availability | ||||

| PTO actuation | Electrohydraulic with adjustable modulation |

| Category | ||||

|---|---|---|---|---|

| Electric power | ||||

| Standard lift capacity | ||||

| Front power take-off (PTO) | ||||

| PTO speed |

| Type | Flange | |||

|---|---|---|---|---|

| Final drive type | Inboard planetary | |||

| Differential controls | ||||

| Axle type | ||||

| Brakes, type and control | ||||

| Rear differential lock | Full-locking electrohydraulic | |||

| Load rating |

| Type | 1700 Series MFWD | |||

|---|---|---|---|---|

| Front axle differential lock | Full-locking electrohydraulic (actuated at same time as rear diff-lock) | |||

| Load rating |

| Front | ||||

|---|---|---|---|---|

| Rear | ||||

| Wheel tread range | ||||

| Turning radius with brakes | ||||

| Turning radius without brakes | 9.14 m 30 ft With 3048-mm (120-in.) tread setting and 457-mm (18-in.) front and rear tracks Measured center of drawbar in U-turn |

|||

| Central Tire Inflation System (CTIS) |

| Tread spacing | Available: 1930.4 mm 76 in. 2032 mm 80 in. 2235.2 mm 88 in. 3048 mm 120 in. |

|||

|---|---|---|---|---|

| Drive type | Camso® 4500 and 6500 General Ag Series - reinforced drive lug technology | |||

| Track width | Available: 457 mm 18 in. 609 mm 24 in. 762 mm 30 in. |

|||

| Mid-rollers | Front: Two Rear: Three |

| Type | Standard: Hydraulic power-steering with electric pump backup |

|---|

| Primary brake (foot brake) | ||||

|---|---|---|---|---|

| Secondary brake | ||||

| Park lock | ||||

| MFWD braking | ||||

| Front axle brakes | ||||

| Auxiliary brakes | ||||

| Hydraulic trailer brakes | ||||

| Pneumatic trailer brakes |

| Alternator size | Standard: 200 amp Optional: 330 amp |

|||

|---|---|---|---|---|

| Battery options | 12 V | |||

| Working lights | Standard: 18 halogen Available: 18 LED 22 LED |

|||

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: halogen, 65 W Available: LED |

|||

| Type of bulb in beacon (Halogen, Zenon, LED) | ||||

| dB(A) rating for backup alarm | ||||

| Total cold cranking amps | 1,850 CCA |

| Rollover protective structure, OOS | ||||

|---|---|---|---|---|

| Seat | Degree of seat swivel, left hand 25 degree (angle) Degree of seat swivel, right hand 40 degree (angle) Standard: air suspension |

|||

| Cab suspension | Standard: four-post cab suspension | |||

| Instructional seat | Standard | |||

| Display | Standard: G5Plus CommandCenter™: 32.5 cm (12.8 in.) with optional G5Plus Extended Monitor | |||

| Radio | Standard: AM/FM Radio, remote controls, auxiliary input jack, four speakers and external antenna Optional 6.4 Touchscreen DAB+ radio with 6.1 channel speaker system and Bluetooth (availability dependent upon destination) |

|||

| Inner cab volume | 3.24 m3 114 cu ft |

|||

| dB(A) rating | ||||

| Cab glass area | 6.52 m2 70.18 sq ft |

|||

| Safety glass rating | ||||

| Front visibility |

| Wheelbase | 3235 mm 127.36 in. |

|||

|---|---|---|---|---|

| Overall width | ||||

| Overall length | ||||

| Overall height | ||||

| Drawbar clearance | ||||

| Front axle center | ||||

| Approximate shipping weight, Open;Cab |

| Base machine weight | e23, 457-mm (18-in.) front/rear and 3048-mm (120-in.) tread: 19,591 kg 43,100 lb |

|||

|---|---|---|---|---|

| Maximum ballast level | 20,000 kg 44,100 lb |

|||

| Maximum permissible weight | 24,000 kg 53,000 lb |

| Crankcase oil volume | 26.6 L 7.0 U.S. gal. |

|||

|---|---|---|---|---|

| Fuel tank capacity | e23: 924 L 244 U.S. gal. EVT: 829 L 219 U.S. gal. |

|||

| Diesel exhaust fluid (DEF) tank | 37.2 L 9.8 U.S. gal. |

|||

| Cooling system | 42.3 L 11.2 U.S. gal. EVT: 46.9 L 12,4 U.S. gal. |

|||

| Transmission-hydraulic system | 1930-mm and 2032-mm (76-in. and 80-in.) tread: 250 L 66.1 U.S. gal. 2235-mm and 3048-mm (88-in. and 120-in.) tread: 260.6 L 68.8 U.S. gal. |

| Interval for engine oil change | 500 hours | |||

|---|---|---|---|---|

| Interval for hydraulic/transmission oil change | 1,500 hours | |||

| Interval for engine coolant change | 6,000 hours |

| Loader | ||||

|---|---|---|---|---|

| Lift capacity at full height | ||||

| Maximum lift height | ||||

| Leveling type |

| Guidance | Standard: StarFire™ Integrated Receiver - SF1; G5Plus CommandCenter AutoTrac, Section Control Activation Optional: StarFire Integrated Receiver - SF-RTK; G5 Advanced Licenses |

|||

|---|---|---|---|---|

| Telematic | Standard: JDLink™ Hardware with Modular Telematics Gateway (MTG), Ethernet Harnesses for CommandCenter (availability dependent upon destination) | |||

| Remote diagnostics |

| AutoTrac ready | ||||

|---|---|---|---|---|

| ISOBUS ready | Standard: ISOBUS Implement Connection (ISO 11783) | |||

| CommandCenter video inputs | Four video inputs for G5Plus Display; optional integrated front and rear cameras | |||

| Immobilizer | ||||

| Side slope rating | ||||

| Uphill/downhill slope rating | ||||

| Country of manufacture | USA |

| Date collected | 01-Apr-2023 |

|---|