1947 – 2022 Self-Propelled Combines

Feeding the World

The development of the self-propelled combine harvester has changed the way the world feeds itself. Today, John Deere combines harvest more than half the world’s grain. The story of their success, from the Model 55 to the X-Series, is one of technical innovation as well as high quality customer support through a network of professional dealers.

1954 Hillside Combine

The self-levelling 55H built on John Deere’s expertise in hillside combines which started with the horse drawn model 36B in 1936. Marketing films promoted many features today’s drivers would recognise: ‘one finger’ power steering, powerful disc brakes and variable speed ground drive.

1963 Tracks

Early tracks were developed from construction machinery. Their steel plates required regular greasing and road speeds were slow. Here they are being used for rice harvesting in Italy. Sharing the familiar triangular profile of today’s tracks, it would take more than 40 years before reliable rubber tracks would become available.

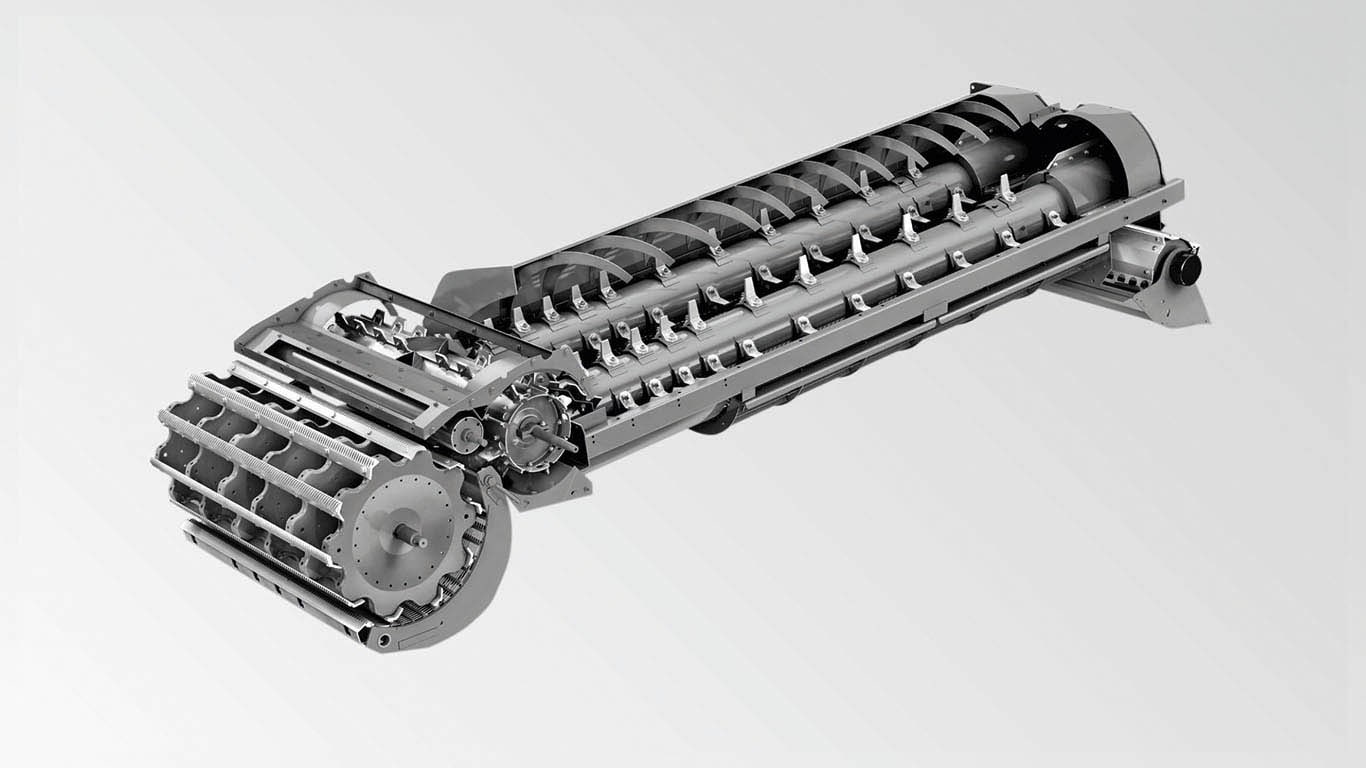

1992 World’s first hybrid combine

The CTS (Cylinder Tine Separator) combine featured a large cylinder and concave upfront with two rotors provided a secondary threshing action. It remained the world’s only hybrid combine until 1996 when John Deere’s patent expired. The compact, narrow body provided exceptional throughput and it is still sold in Asia for rice harvesting.

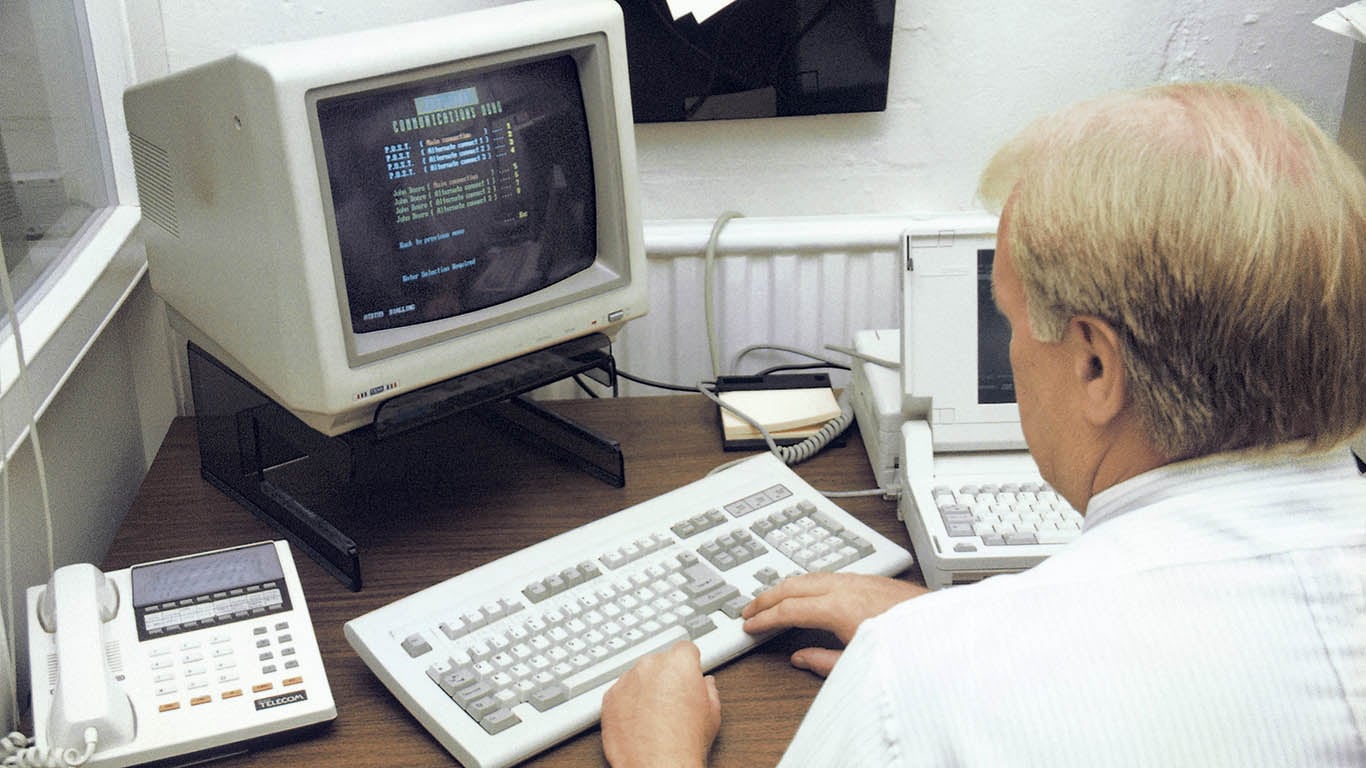

1999 Greenstar 1 Display

Featuring Parallel Tracking the driver had to concentrate hard to keep the combine on the centre line. It wasn’t until AutoTrac in 2002 that true hands-free guidance arrived. The display also featured Harvest Monitor and Yield Mapping software and many are still in use today.

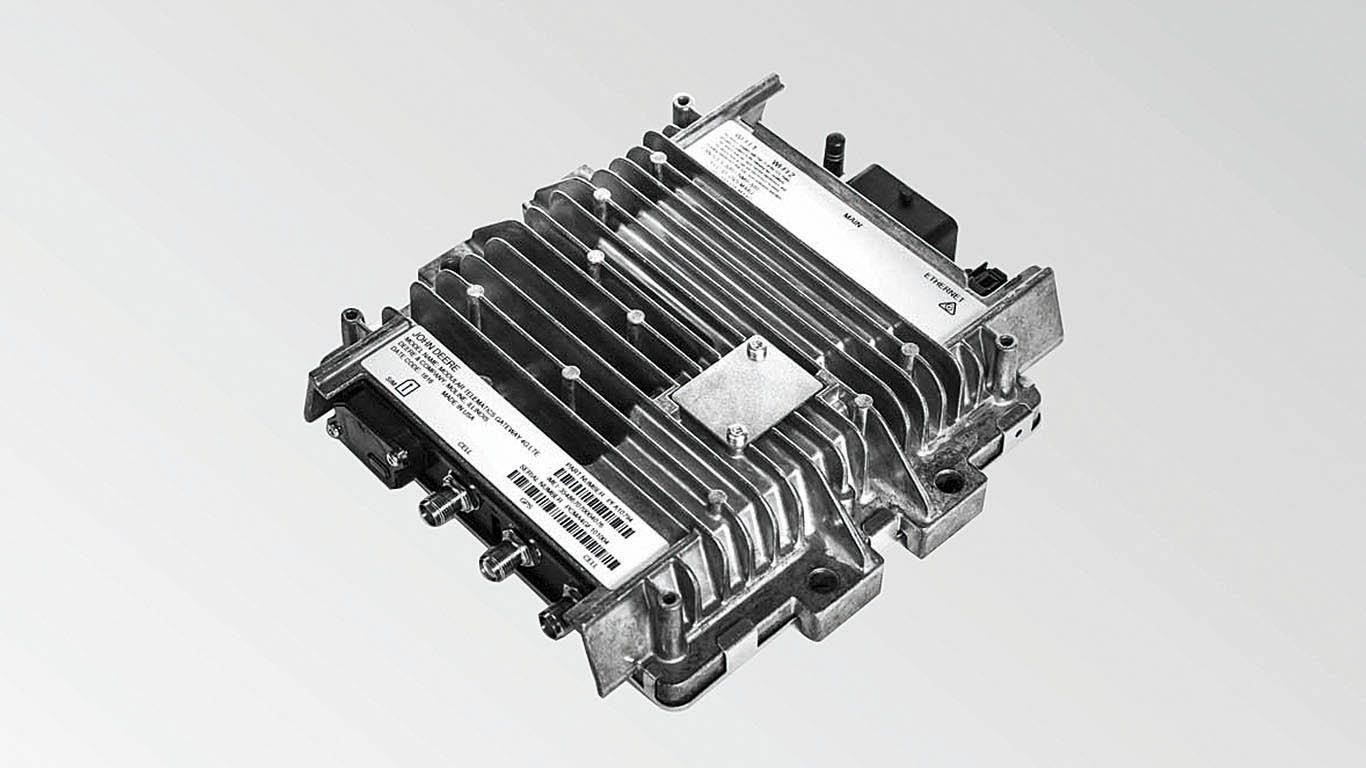

2002 Machine Connectivity

Early combine fleets used flags to signal which combine needed unloading. Then came short wave radio and mobile phones. The introduction of onboard electronics to enable JDLink machine connectivity is the biggest harvesting innovation of the past 20 years. Transmitting real-time data on machine performance and positioning for remote monitoring, it’s transforming work planning, harvest logistics and more.

2010 500,000th Combine

Greg Briggs from Cisco, Illinois took delivery of the 500,000th John Deere combine, a 9870 STS on 20th May 2010. The Single Tine Separator System was a major departure from the traditional walker system and is so successful it lives on today in the S-Series combines - the world’s most popular combine.

75 Years of Innovation

See the combines of the past in action and the key milestones that have transformed harvesting productivity and allowed the world to feed up to 7.8 bn people today.

1997 John Deere Financial in Europe

Finance has been extremely important ever since the Great Depression in the 1930s when John Deere extended credit terms to struggling farmers. In later years, with the creation of John Deere Financial in the UK in 1997, a foothold in Europe was established and more flexible financing options have become available to meet the challenges of individual farmers.

Fast forward to the future

Find out what an upgrade to our latest combines can do for you.